Comprehensive solution

Reliable modern systems from top South-East Asian manufacturers

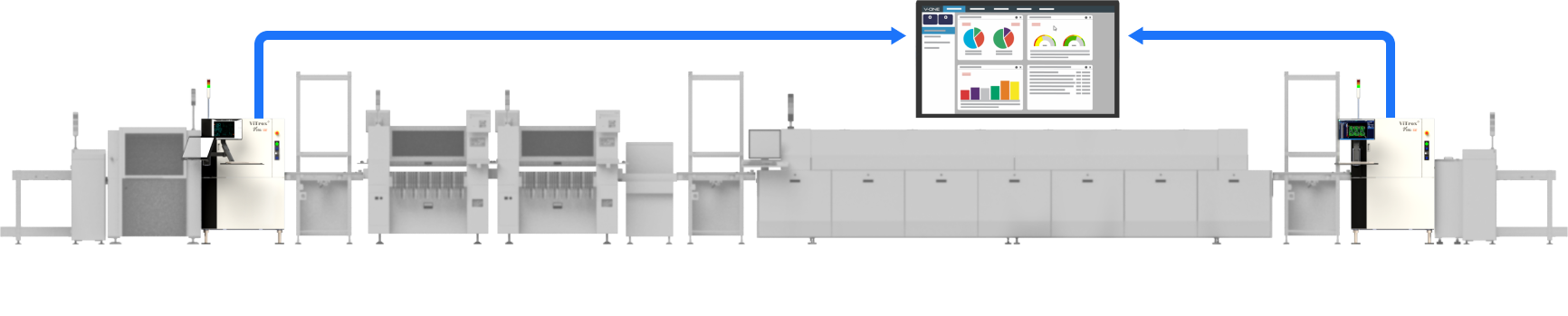

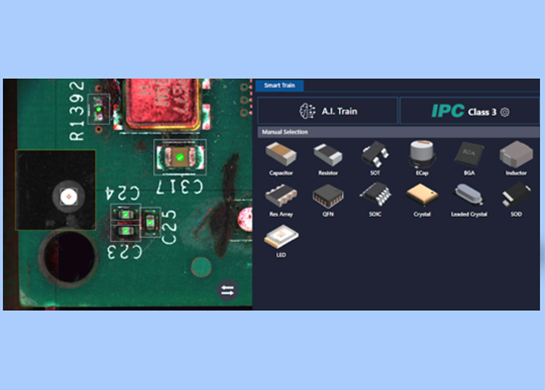

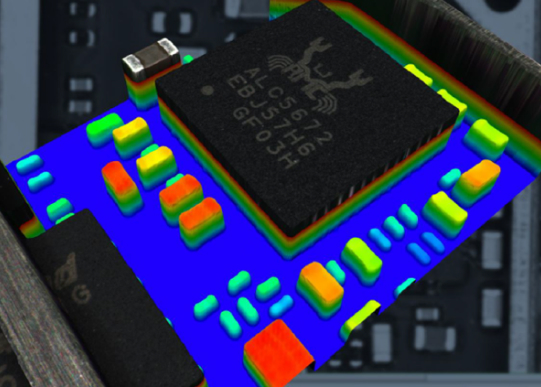

A set of tools to automate the preparation of work programs, monitoring and verification

Complex of software and hardware on a single platform, simplifying the integration of systems in lines

A set of activities for successful start of manufacturing process and training of specialists