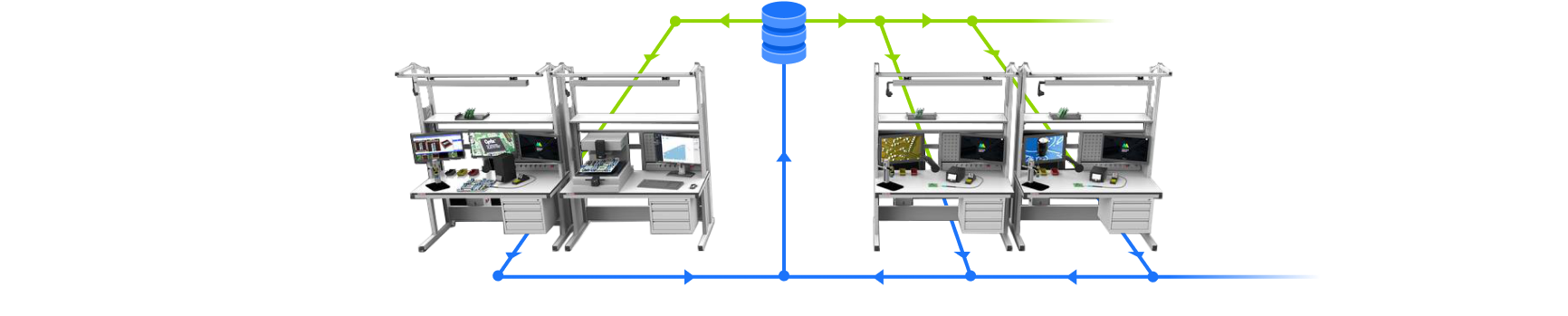

Comprehensive solution

Equipped workstations for simple and complex repairs, connected to the program-analytical system

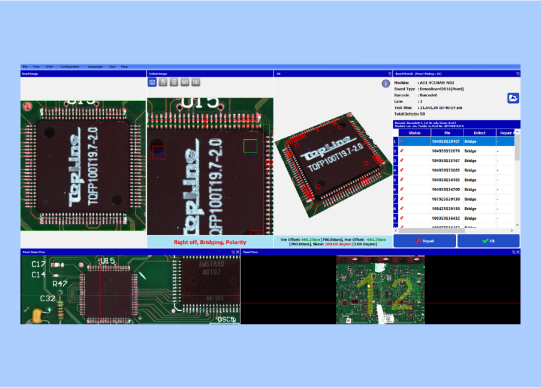

Easy access to summary information from automatic control systems, schematics and technical documentation

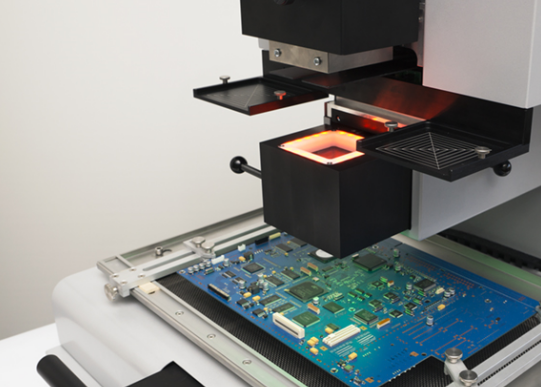

The solution includes a modern hybrid type repair center from a top manufacturer

Comfortable, functional, safe and well-equipped workstations that take into account international practice