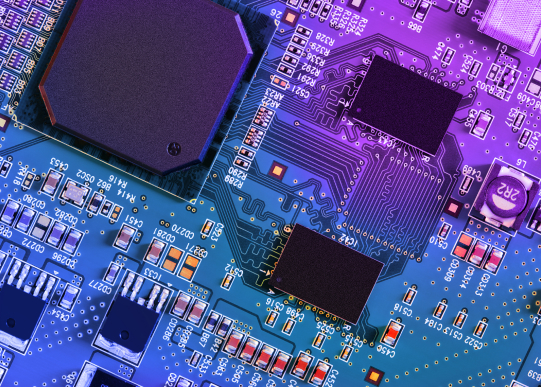

Comprehensive solution

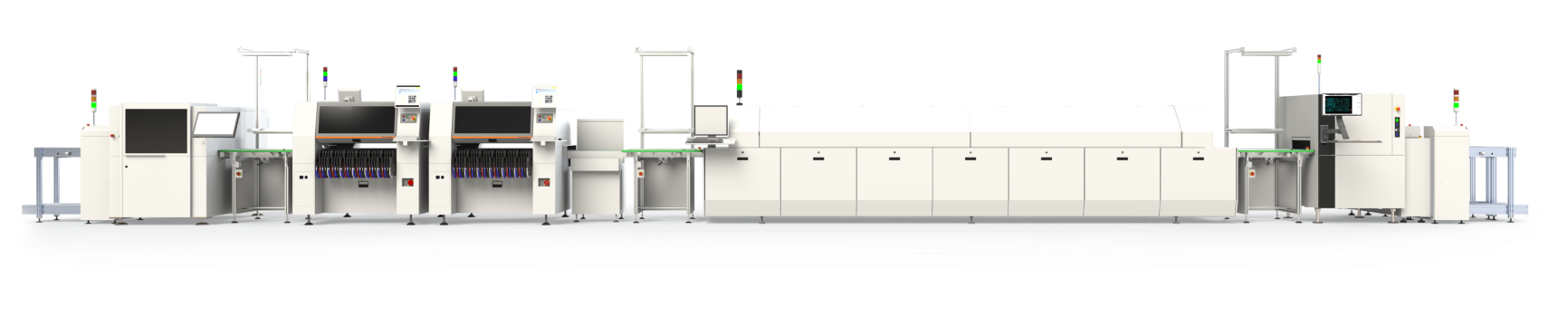

Reliable modern systems from top South-East Asian manufacturers

A complex of tools for automatisation, traceability of manufacturing process and protection from human errors

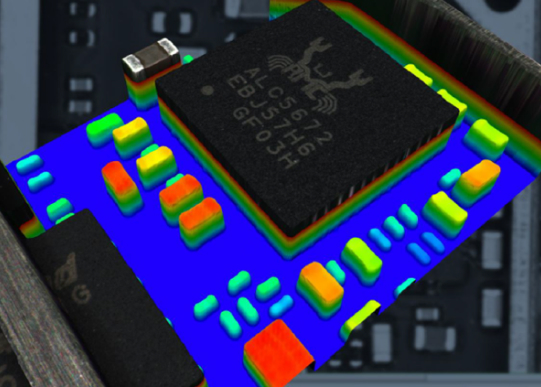

A complex of software and hardware for quality control in technology process

A set of activities for successful start of manufacturing process and training of specialists