Comprehensive solution

Reliable modern systems from top South-East Asian manufacturers

A complex of tools for automatisation, traceability of manufacturing process and protection from human errors

A complex of software and hardware for quality control in technology process

A set of activities for successful start of manufacturing process and training of specialists

FLEX:THT KEY FEATURES

A monitor with interactive instructions is provided at each workstation for the manual installation of components of the FLEX:THT complex.

The basis of this solution is the “Smart Workstation” software and hardware complex developed by our team, which has proven itself in the tasks of automating manual operations.

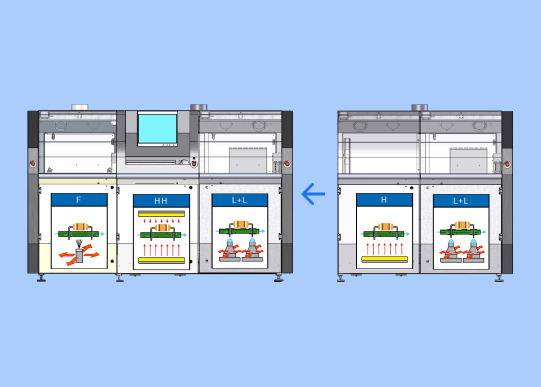

FLEX:THT solution includes a dual selective soldering system that provides high flexibility and efficient soldering of various board designs.

This allow the simultaneous use of two different nozzles designed for different tasks, for example, a wide one for soldering multi-pin connectors and a narrow one for soldering single pins.

In the selective soldering system of the FLEX:THT line, it is possible to increase productivity by attaching additional soldering modules.

This will quickly modernize the line and increase production capacity.

The highest quality soldering in accordance with the requirements for products of 2 and 3 classes of the IPC-610 standard with minimal human impact due to the configuration of the soldering module:

- Advanced electromagnetic pumps for consistent solder wave and no vibration.

- PCB warping compensation system that automatically corrects the position of the nozzle relative to the PCB.

- Board heating system from above.

- Automatic solder feeder for a stable solder residue in the bath and the elimination of "drawdown" of the wave.

- Mini wave height automatic control system.

- Automatic nozzle cleaning system.

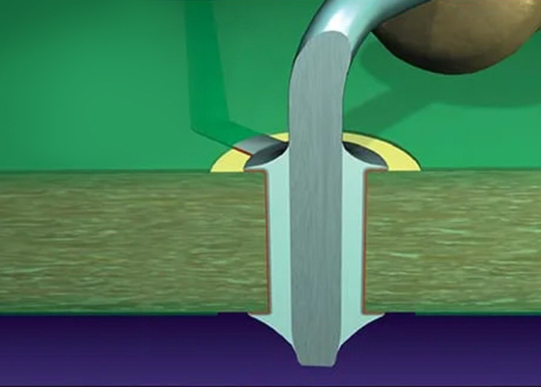

When working with heat-intensive and large boards, high-quality preheating and maintaining the soldering temperature throughout the process are extremely important. This is necessary to ensure the capillary effect and high-quality filling of holes in the printed circuit board and the formation of a reliable solder joint that meets the requirements of the IPC-610 standard for products of 2 and 3 classes.

To solve this problem, the configuration of the selective soldering system provides additional modules for heating the board from above — both in the preheating zone and in the soldering zone. This allows you to effectively warm up the board before soldering and maintain its temperature in the process.

The program of technological and service support included in the solution is aimed at achieving target production indicators on time. The program includes:

- Programs development for the main product.

- Multi-level program of personnel training.

- Technology consulting.

- Full warranty - 3 years.

FLEX solutions was chosen according to the principle “nothing excessive and everything needed”. The reasonable cost of an advanced high-tech solution is provided by:

- Deep expertise and colossal experience of the FLEX team.

- Equipment manufacturers in South-East Asia.

- A balanced approach to the configuration of each solution in the complex.

years of successful

work

implemented

projects

customer

satisfaction

service

support