Comprehensive solution

Reliable modern systems from top South-East Asian manufacturer

The system is integrated with the V-ONE analytics complex, ensuring the implementation of the Industry 4.0 principles

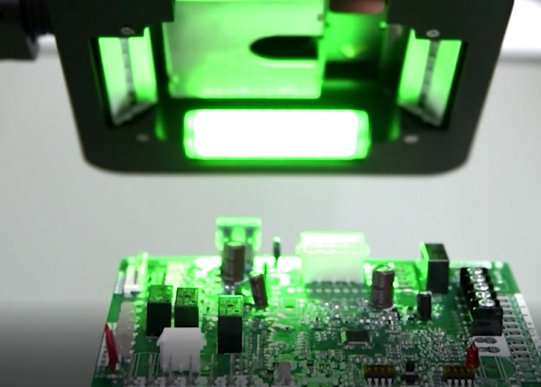

The solution allows to organize optical robotic quality control on different manufacturing stages

A set of activities for successful start of manufacturing process and training of specialists